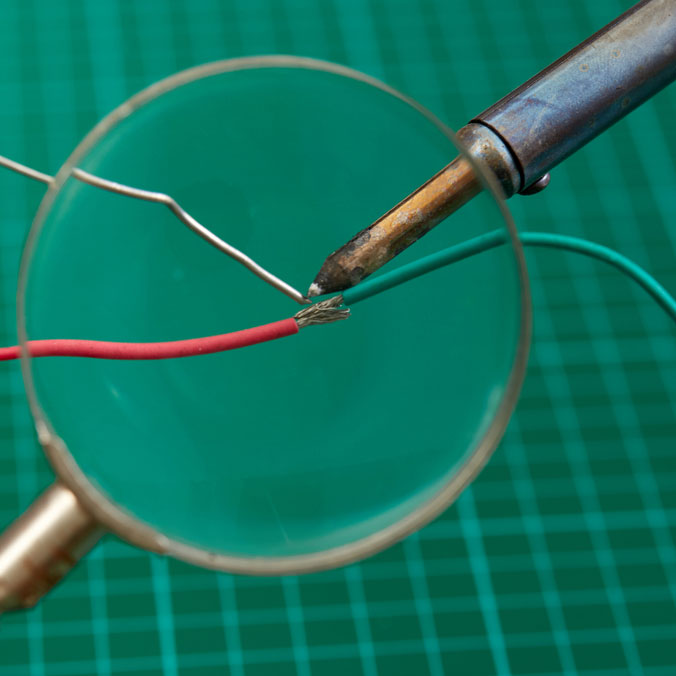

Our solders come in wire, bar, and rod forms. Browse below or learn more by selecting what metal(s) you’re working with:

Solders for Aluminum, Diecast, Zamak, and White Metal

What joins Aluminum to Aluminum or Aluminum to Copper?

- Product: KappAloy™

- Material: Tin-Zinc

- Melting Temp: Begins at 390°F (199°C)

- Traits: Excellent corrosion resistance and tensile strength.

- Used for: Heating panels, high voltage components, sound equipment, radiators, and to spray molds, patterns, trophies, and capacitors

What joins Aluminum and Aluminum/Copper radiators and heat exchangers?

- Product: KappRad™

- Material: Tin-Zinc-Cadmium

- Melting Temp: Begins at 355°F (179°C)

- Traits: A lower melting point makes delicate repair work easier.

- Used for: Repairing radiators and heat exchangers

What repairs Aluminum, Zinc Diecast, Pot Metal, and White Metal?

- Product: Alumite™

- Material: Zinc-Aluminum

- Melting Temp: Begins at 715°F (379°C)

- Traits: Excellent repair and general purpose high strength solders

- Used for: Fabrication, maintenance, and repair of Aluminum, Zinc Diecast, Pot Metal, and White Metal alloys.

What joins most metals, including aluminum, in high stress, high vibration environments?

- Product: KappCad™

- Material: Cadmium-Zinc

- Melting Temp: Begins at 509°F (265°C)

- Traits: strong, corrosion resistant

- Used for: joints on most metals, but works especially well on Aluminum to Aluminum and Aluminum to Copper joints

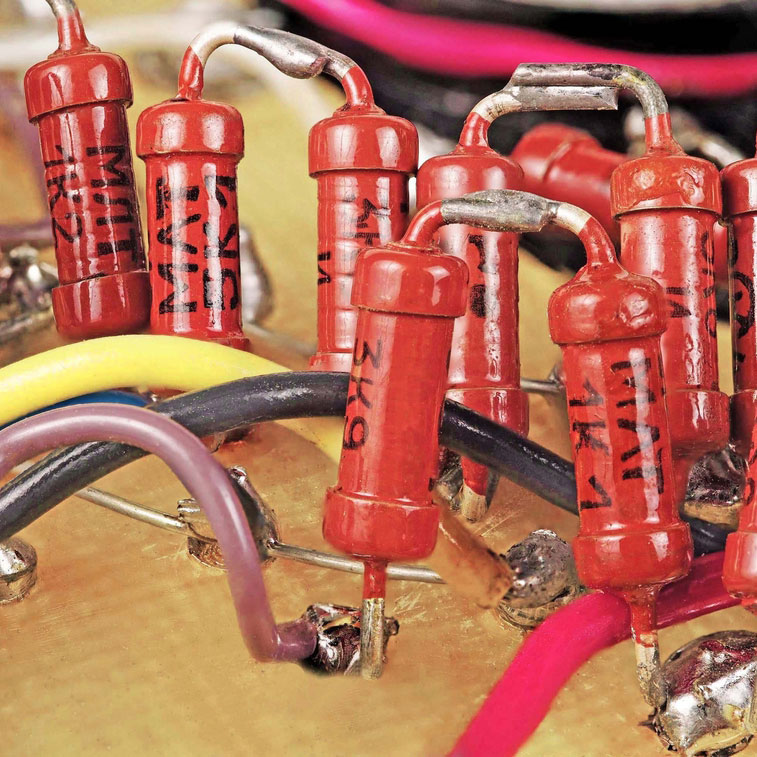

Solders for Copper, Brass, and Stainless Steel

What is best for soldering electronics? Or for high pressure/stress plumbing?

- Product: KappZapp™

- Material: Tin-Silver

- Melting Temp: Begins at 423°F (221°C) or 430°F (217°C), depending on formulation

- Traits: strength and vibration resistance, NSF certified lead-free

- Used for: electronics, plumbing and potable water projects, joins most ferrous and non-ferrous metals including Copper, Brass, and Stainless Steel.

What lead-free solder is best for household plumbing?

- Product: KappFree™ or KappFreeA™(acid core)

- Material: Tin, copper, silver

- Melting Temp: Begins at 440°F (226°C)

- Traits: Lead-free, Cadmium-free higher electrical conductivity & lower cost

- Used for: plumbing industry standard for joints.

What is ideal for stainless steel to stainless steel or copper?

- Product: KappTec™ or KappTecZ™

- Material: Cadmium-Silver

- Melting Temp: Begins at 640°F (338°C) and 480°F (249°C), respectively

- Traits: high temperature, high strength, high vibration & high stress resistance

- Used for: general purpose solder for all solderable metals except Aluminum. It is highly recommended for Stainless Steel to Stainless Steel or Copper soldering. This alloy is outstanding in. Its high electrical conductivity versus other solders makes it an excellent choice for electrical applications.

What is a lower cost solution for plumbing and stainless steel applications?

- Product: KappCu™

- Material: Tin-Copper

- Melting Temp: Begins at 441°F (227°C)

- Traits: NSF lead free compliant solder, high workable range

- Used for: plumbing and Stainless Steel soldering applications, allows for joint build-up and adjustment during cooling.

What is a low cost solution for electronic applications and stained glass?

- Product: KappLead™

- Material: Tin-Lead

- Melting Temp: Begins at 361°F (183°C)

- Traits: low cost, 99.999% pure virgin Lead, good flow and consistency

- Used for: stronger, more ductile joints. KappLead40™ is the Stained Glass industry standard for sensitive restorations and new installations.

What is the most time and energy efficient solder for electronics?

- Product: Kapp Electric Eutectic™

- Material: Tin-Lead-Silver

- Melting Temp: Begins at 354°F (179°C)

- Traits: low application temperature, eutectic, high strength and vibration/stress resistance

- Used for: uses less energy and requires less time and post-production cleanup, often requiring only inspection. It also eliminates the effects of high heat used in higher temperature brazing – avoiding electronic material degradation, base metal deformation, discoloration, segregation, annealment, and heat related oxide-scale formation.

What is a lead free soldering solution for electronics, copper tubing, and cooling coils?

- Product: KappAnt™

- Material: Tin-Antimony

- Melting Temp: Begins at 452°F (234°C)

- Traits: low cost, NSF compliant Lead-free replacement for Tin-Lead solder, moderate strength

- Used for: electrical equipment, Copper tubing, and cooling coils for refrigerators. Joints are of where the higher strength and higher cost of KappFree™ or KappZapp™ Tin-Silver solders are not necessary. KappAnt’s higher Tin content provides higher electrical conductivity than a high Lead solder in electrical/electronic joints. Also used where Lead may be a hazard - for instance, in contact with foodstuffs or potable water pipes. KappAnt™ solder is suitable for use at higher temperatures than KappLead™ solders.

Solders for Repairing Galvanized Coatings on Steel

What works on galvanized steel?

- Product: Kapp Galvanite™

- Material: Tin-Zinc-Copper

- Melting Temp: Begins at 390°F (200°C)

- Traits: Lead-free, works on galvanized steel

- Used for: manufacturing and field applications that require a seamless protective barrier

Solders for Auto Body Repair and Buildup

What works best to repair or prevent rusted autobody parts?

- Product: Kapp Autobody™

- Material: Tin-Zinc-Copper

- Melting Temp: Begins at 390°F (200°C)

- Traits: Lead-free, works on galvanized steel

- Used for: autobody applications to prevent rusting through a protective barrier